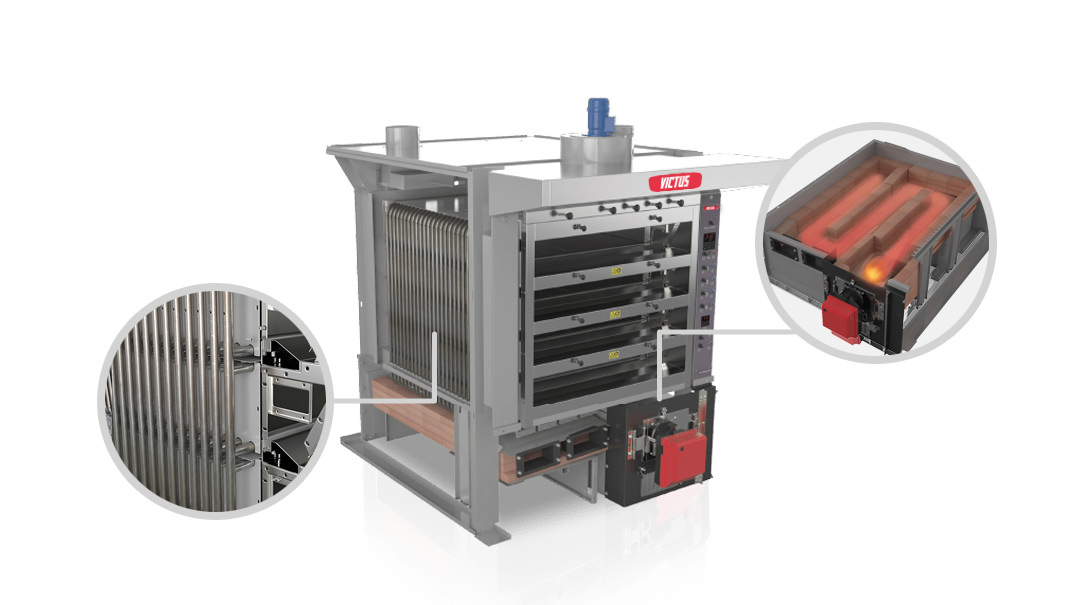

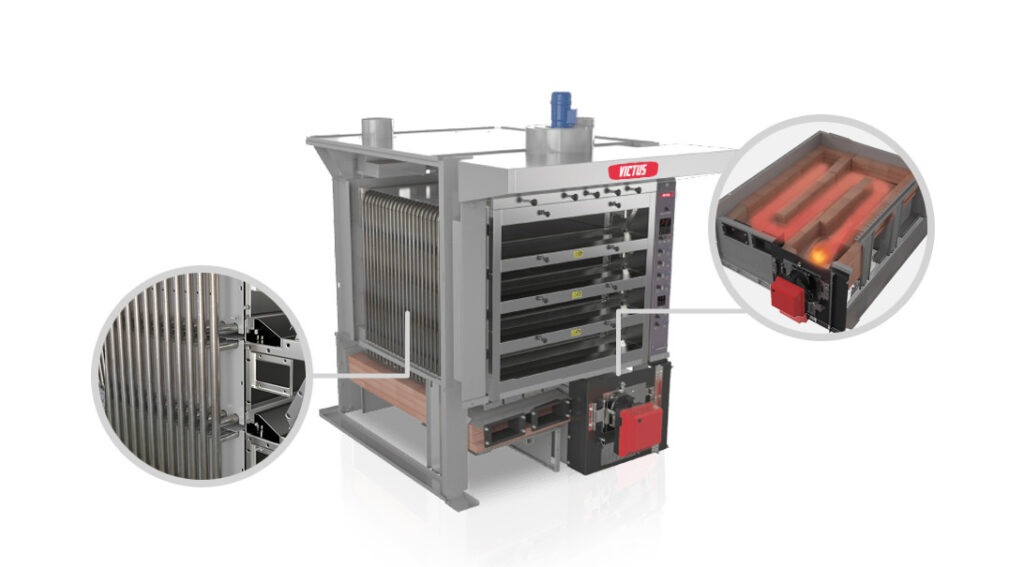

Saturno

Heavy steam tube oven

Steam tube oven built in concrete with high thermal inertia, able to ensure top quality and uniform baking thanks to the perfectly even heat distribution within its chambers.

Perfect for large loaves

Thanks to its high thermal capacity, Saturno can bake without problems loaves up to 2000 grams. The independent steam generators for each chamber can inject the right amount of steam to the product throughout the whole baking process.

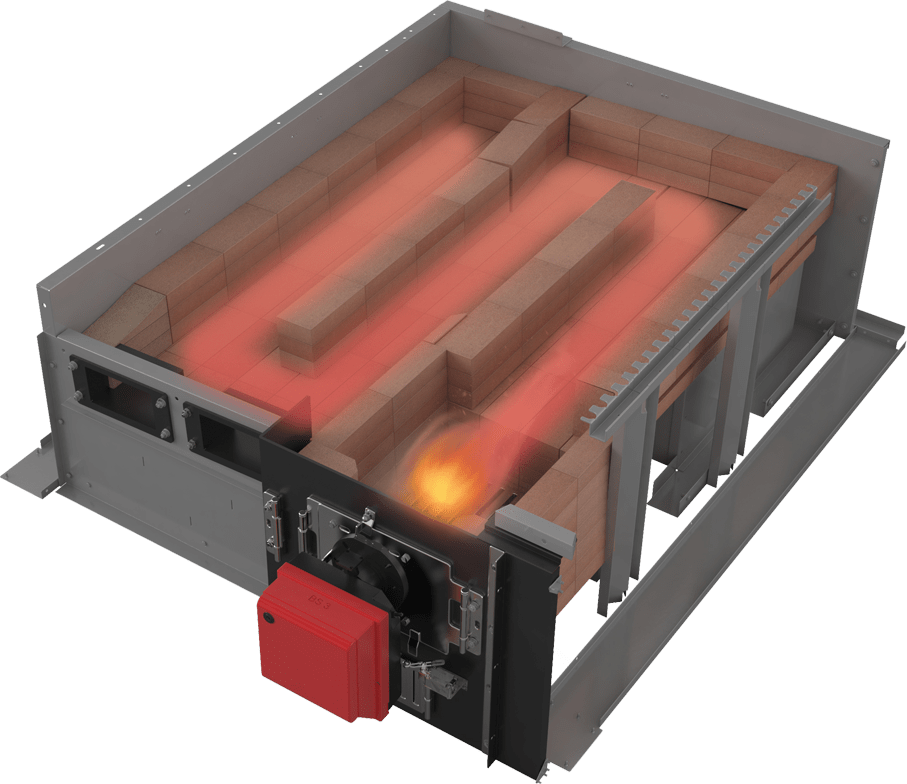

The annular tube baking system

The overheated steam starts circulating inside the tubes, warming up all the chambers. Two separated tubes heat the top and bottom of adjacent chambers, to maximize the thermal transfer towards the product.

The flame in the refractory channel heats the stainless-steel tubes above, vaporising the water inside them.

The annular tube baking system

Energy savings

The coating is made of highly insulating material, which considerably reduces heat dispersions towards the environment, thus allowing the oven to maintain the set temperature with limited energy consumption.

Maximized thermal capacity

The tubes are completely wrapped in concrete, the firebox and channels are made of refractory material with high content of aluminium oxide. These executive details give Saturno the highest thermal inertia, accumulating the combustion heat and distributing it evenly across the different chambers.

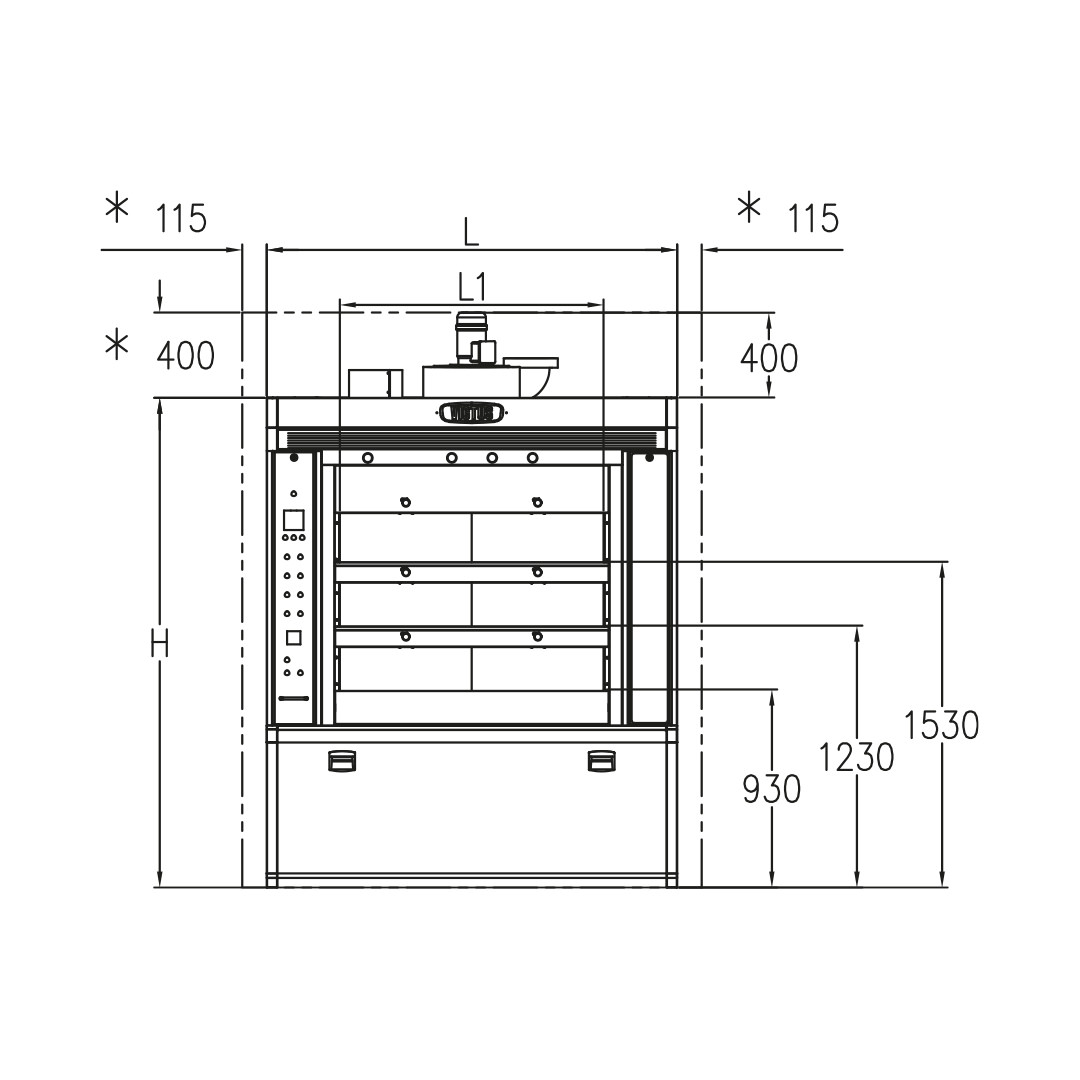

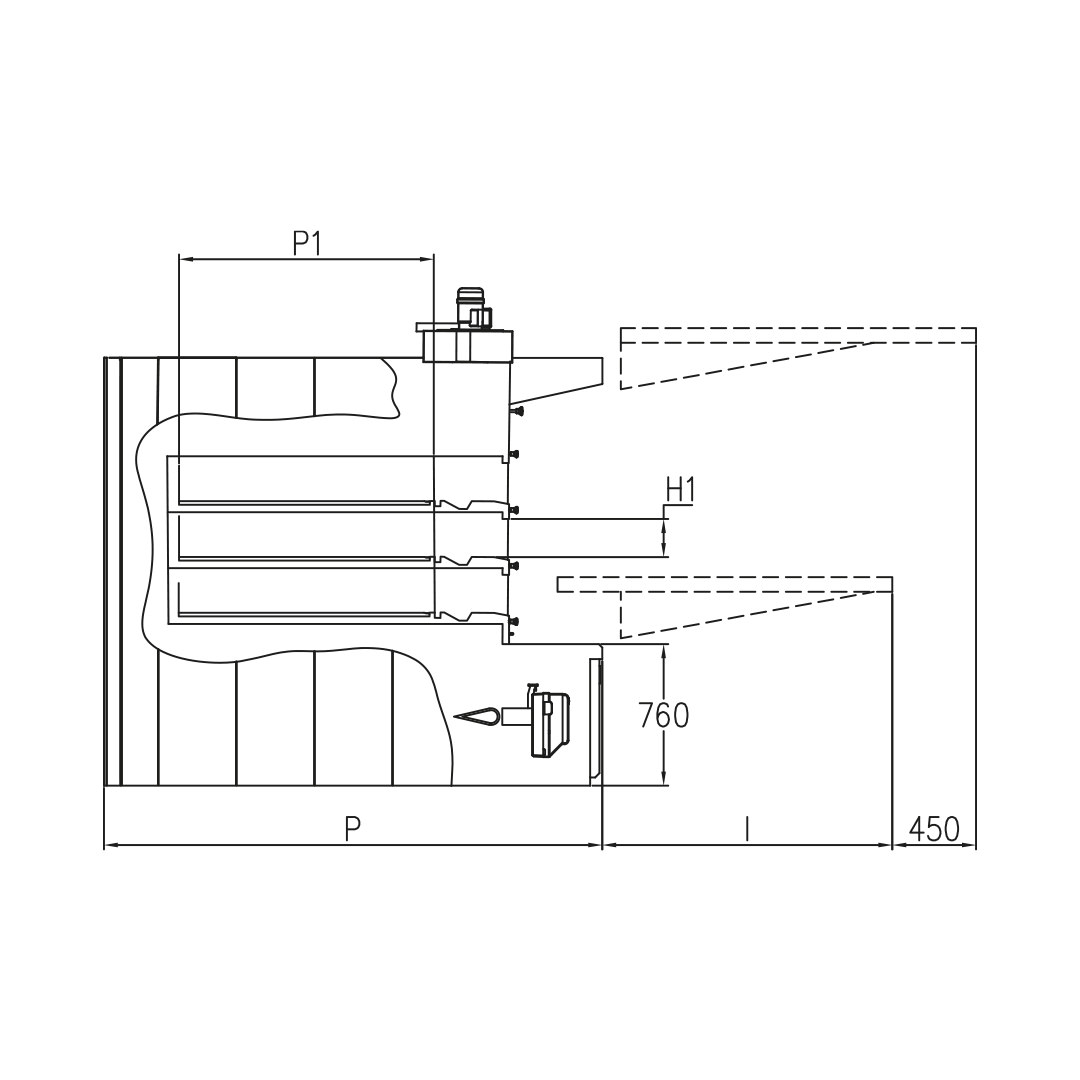

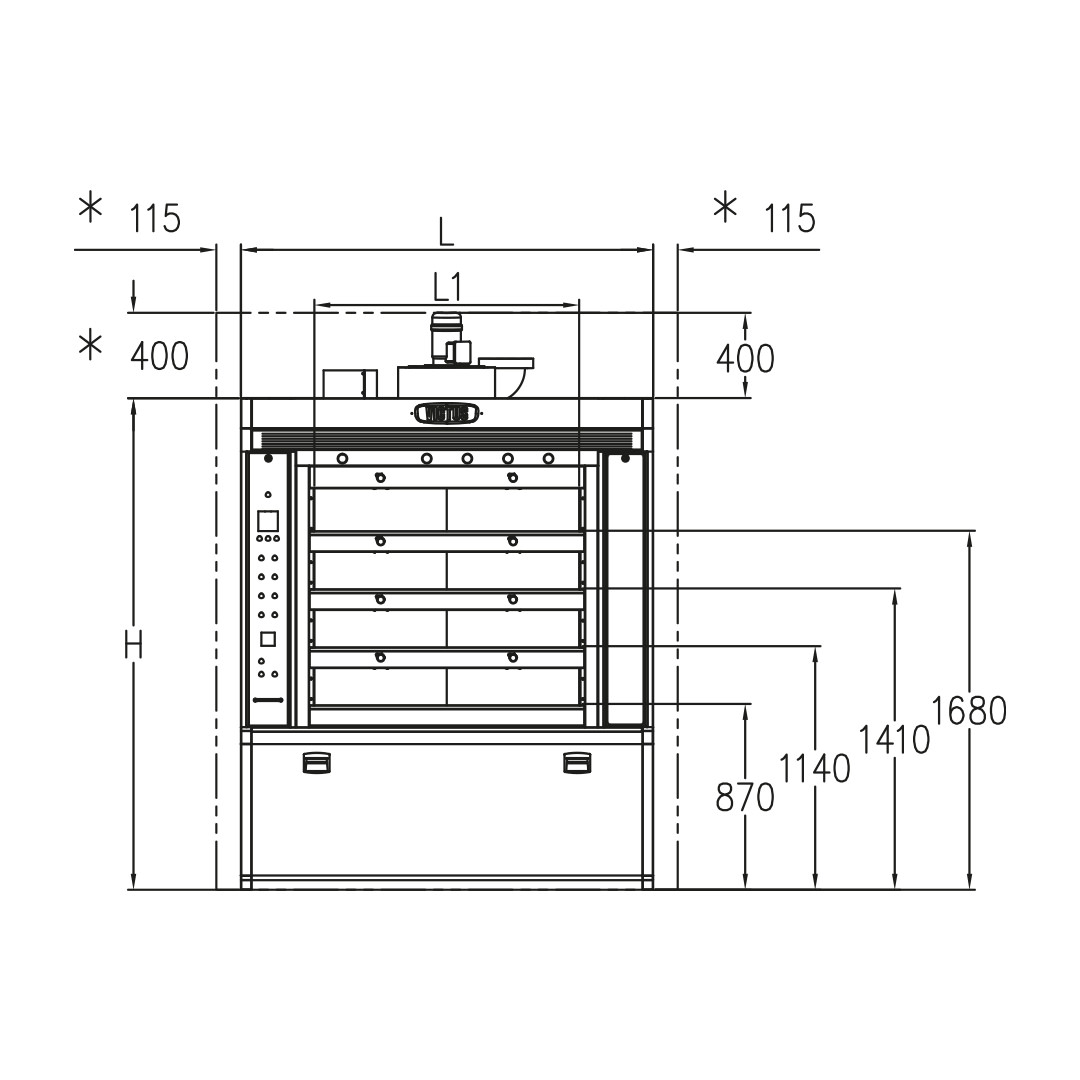

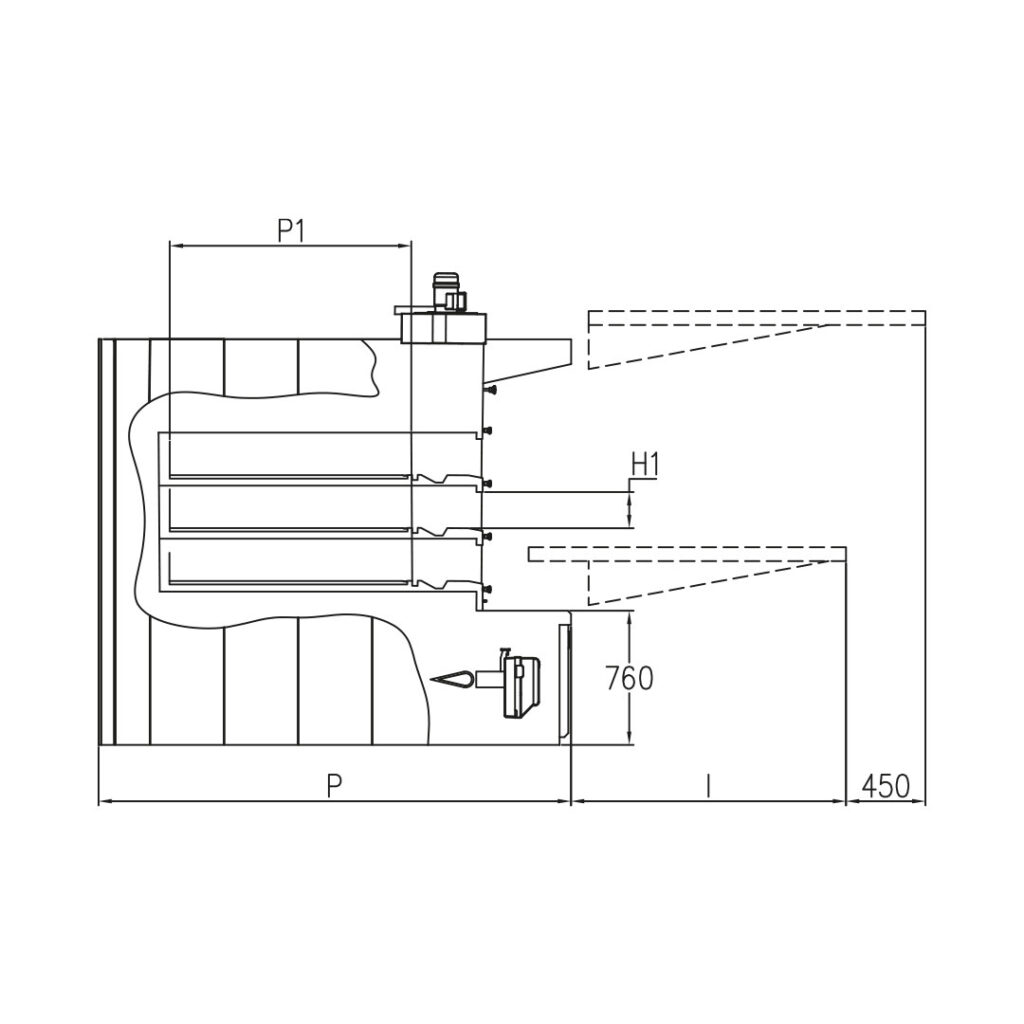

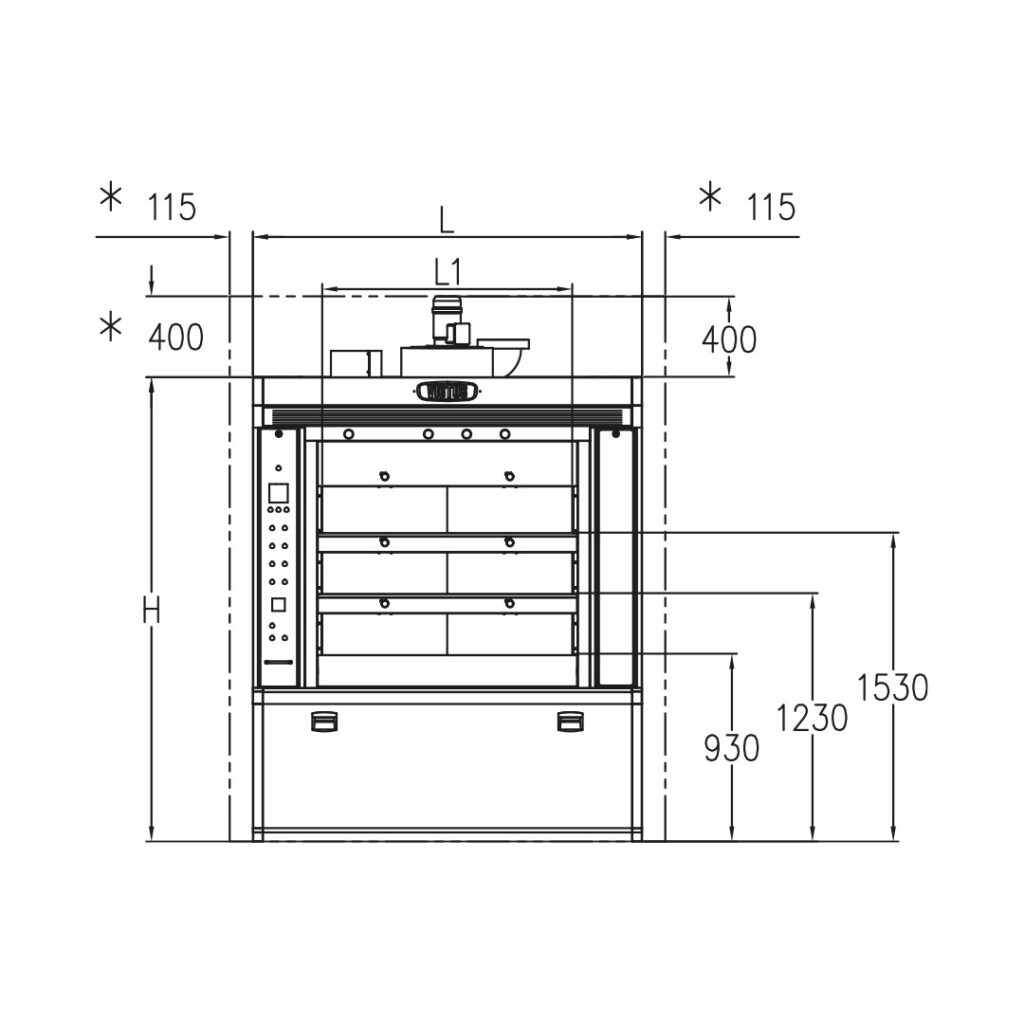

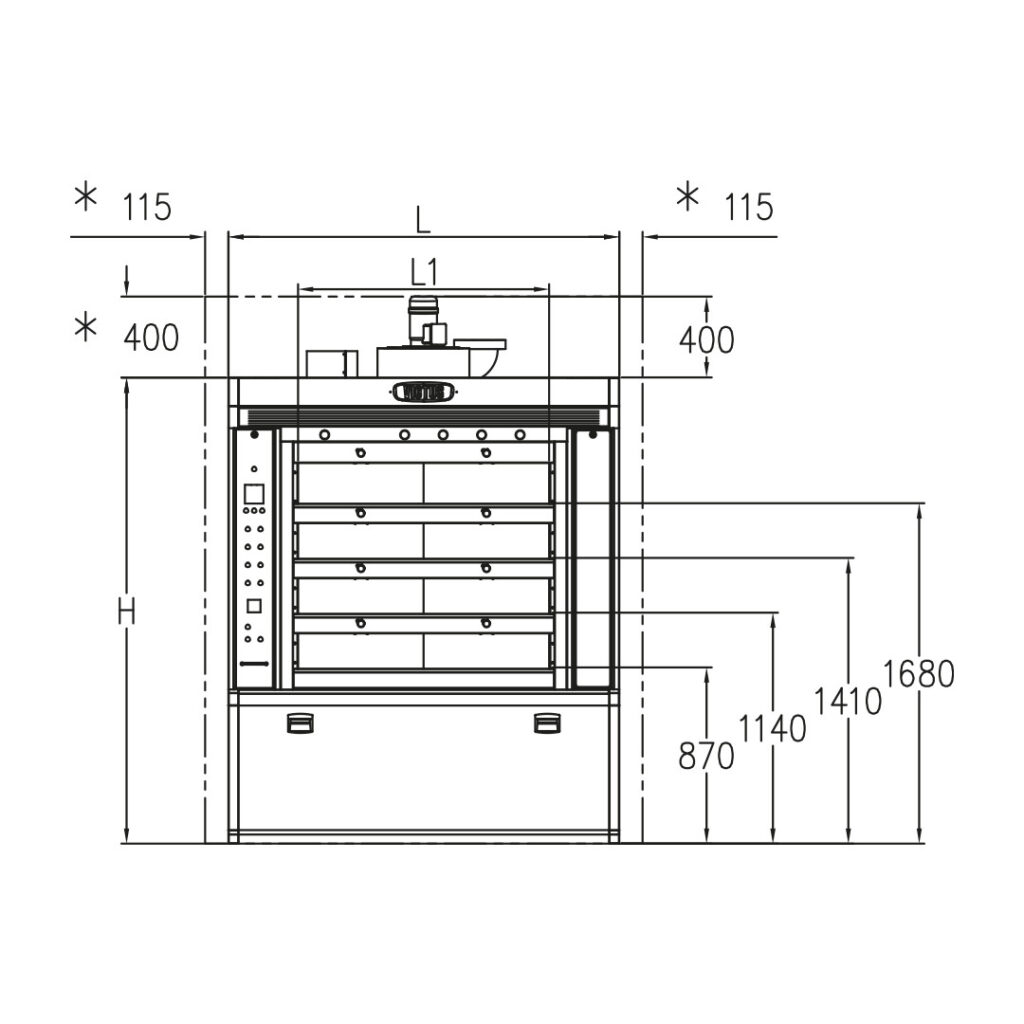

Find the model that best suits your needs

Select the baking surface range that you need and choose among our models the one with the dimensions that fit your spaces.

| Model | Baking surface [m2] | Chambers | Chamber internal width L1 [mm] | Chamber internal depth P1 [mm] | Chamber internal heigth H1 [mm] | Oven mouth passage upper chamber [mm] | Doors per deck | Width L [mm] | Depth P [mm] | Height H [mm] | Thermal power [kW] | Thermal Power [kcal] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TAC 3.12/13 | 5,0 | 3 | 1.240 | 1.370 | 190 | 185 | 2 | 1.930 | 2.680 | 2.300 | 52 | 45.000 |

| TAC 3.12/16 | 6,0 | 3 | 1.240 | 1.600 | 190 | 185 | 2 | 1.930 | 2.910 | 2.300 | 62 | 53.400 |

| TAC 3.12/18 | 6,7 | 3 | 1.240 | 1.800 | 190 | 185 | 2 | 1.930 | 3.100 | 2.300 | 69 | 60.300 |

| TAC 4.12/13 | 6,8 | 4 | 1.240 | 1.370 | 160 | 185 | 2 | 1.930 | 2.680 | 2.300 | 62 | 54.400 |

| TAC 3.12/20 | 7,4 | 3 | 1.240 | 2.000 | 190 | 185 | 2 | 1.930 | 3.310 | 2.300 | 77 | 66.600 |

| TAC 3.18/13 | 7,6 | 3 | 1.860 | 1.370 | 190 | 185 | 3 | 2.550 | 2.680 | 2.300 | 70 | 60.800 |

| Model | Baking surface [m2] | Chambers | Chamber internal width L1 [mm] | Chamber internal depth P1 [mm] | Chamber internal heigth H1 [mm] | Oven mouth passage upper chamber [mm] | Doors per deck | Width L [mm] | Depth P [mm] | Height H [mm] | Thermal power [kW] | Thermal Power [kcal] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TAC 4.12/16 | 8,0 | 4 | 1.240 | 1.600 | 160 | 185 | 2 | 1.930 | 2.910 | 2.300 | 74 | 63.200 |

| TAC 3.12/22 | 8,2 | 3 | 1.240 | 2.210 | 190 | 185 | 2 | 1.930 | 3.520 | 2.300 | 85 | 73.800 |

| TAC 4.12/18 | 8,9 | 4 | 1.240 | 1.800 | 160 | 185 | 2 | 1.930 | 3.100 | 2.300 | 82 | 71.200 |

| TAC 3.12/24 | 9,0 | 3 | 1.240 | 2.420 | 190 | 185 | 2 | 1.930 | 3.730 | 2.300 | 94 | 81.000 |

| TAC 3.18/16 | 9,0 | 3 | 1.860 | 1.600 | 190 | 185 | 3 | 2.550 | 2.910 | 2.300 | 83 | 71.400 |

| TAC 3.18/18 | 10,0 | 3 | 1.860 | 1.800 | 190 | 185 | 3 | 2.550 | 3.100 | 2.300 | 93 | 80.000 |

| TAC 4.12/20 | 10,0 | 4 | 1.240 | 2.000 | 160 | 185 | 2 | 1.930 | 3.310 | 2.300 | 93 | 80.000 |

| TAC 4.18/13 | 10,2 | 4 | 1.860 | 1.370 | 160 | 185 | 3 | 2.550 | 2.680 | 2.300 | 94 | 81.600 |

| Model | Baking surface [m2] | Chambers | Chamber internal width L1 [mm] | Chamber internal depth P1 [mm] | Chamber internal heigth H1 [mm] | Oven mouth passage upper chamber [mm] | Doors per deck | Width L [mm] | Depth P [mm] | Height H [mm] | Thermal power [kW] | Thermal Power [kcal] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TAC 4.12/22 | 11,0 | 4 | 1.240 | 2.210 | 160 | 185 | 2 | 1.930 | 3.520 | 2.300 | 102 | 88.000 |

| TAC 3.18/20 | 11,1 | 3 | 1.860 | 2.000 | 190 | 185 | 3 | 2.550 | 3.310 | 2.300 | 103 | 88.800 |

| TAC 4.12/24 | 12,0 | 4 | 1.240 | 2.420 | 160 | 185 | 2 | 1.930 | 3.730 | 2.300 | 111 | 96.000 |

| TAC 4.18/16 | 12,0 | 4 | 1.860 | 1.600 | 160 | 185 | 3 | 2.550 | 2.910 | 2.300 | 109 | 94.600 |

| TAC 3.18/22 | 12,3 | 3 | 1.860 | 2.210 | 190 | 185 | 3 | 2.550 | 3.520 | 2.300 | 114 | 98.400 |

| TAC 3.24/18 | 13,3 | 3 | 2.480 | 1.800 | 190 | 185 | 4 | 3.170 | 3.100 | 2.300 | 123 | 106.400 |

| TAC 4.18/18 | 13,3 | 4 | 1.860 | 1.800 | 160 | 185 | 3 | 2.550 | 3.100 | 2.300 | 121 | 104.400 |

| TAC 3.18/24 | 13,5 | 3 | 1.860 | 2.420 | 190 | 185 | 3 | 2.550 | 3.730 | 2.300 | 125 | 108.000 |

| Model | Baking surface [m2] | Chambers | Chamber internal width L1 [mm] | Chamber internal depth P1 [mm] | Chamber internal heigth H1 [mm] | Oven mouth passage upper chamber [mm] | Doors per deck | Width L [mm] | Depth P [mm] | Height H [mm] | Thermal power [kW] | Thermal Power [kcal] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TAC 3.18/26 | 14,6 | 3 | 1.860 | 2.630 | 190 | 185 | 3 | 2.550 | 3.940 | 2.300 | 136 | 116.800 |

| TAC 3.24/20 | 14,8 | 3 | 2.480 | 2.000 | 190 | 185 | 4 | 3.170 | 3.310 | 2.300 | 137 | 118.400 |

| TAC 4.18/20 | 14,8 | 4 | 1.860 | 2.000 | 160 | 185 | 3 | 2.550 | 3.310 | 2.300 | 137 | 118.400 |

| TAC 3.24/22 | 16,4 | 3 | 2.480 | 2.210 | 190 | 185 | 4 | 3.170 | 3.520 | 2.300 | 152 | 131.200 |

| TAC 4.18/22 | 16,4 | 4 | 1.860 | 2.210 | 160 | 185 | 3 | 2.550 | 3.520 | 2.300 | 152 | 131.200 |

| TAC 4.24/18 | 17,7 | 4 | 2.480 | 1.800 | 160 | 185 | 4 | 3.170 | 3.100 | 2.300 | 154 | 132.700 |

| Model | Baking surface [m2] | Chambers | Chamber internal width L1 [mm] | Chamber internal depth P1 [mm] | Chamber internal heigth H1 [mm] | Oven mouth passage upper chamber [mm] | Doors per deck | Width L [mm] | Depth P [mm] | Height H [mm] | Thermal power [kW] | Thermal Power [kcal] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TAC 3.24/24 | 18,0 | 3 | 2.480 | 2.420 | 190 | 185 | 4 | 3.170 | 3.730 | 2.300 | 167 | 144.000 |

| TAC 4.18/24 | 18,0 | 4 | 1.860 | 2.420 | 160 | 185 | 3 | 2.550 | 3.730 | 2.300 | 167 | 144.000 |

| TAC 3.24/26 | 19,5 | 3 | 2.480 | 2.630 | 190 | 185 | 4 | 3.170 | 3.940 | 2.300 | 181 | 156.000 |

| TAC 4.18/26 | 19,5 | 4 | 1.860 | 2.630 | 160 | 185 | 3 | 2.550 | 3.940 | 2.300 | 181 | 156.000 |

| 19,8 | 4 | 2.480 | 2.000 | 160 | 185 | 4 | 3.170 | 3.310 | 2.300 | 172 | 148.500 |

| Model | Baking surface [m2] | Chambers | Chamber internal width L1 [mm] | Chamber internal depth P1 [mm] | Chamber internal heigth H1 [mm] | Oven mouth passage upper chamber [mm] | Doors per deck | Width L [mm] | Depth P [mm] | Height H [mm] | Thermal power [kW] | Thermal Power [kcal] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TAC 3.24/28 | 21,1 | 3 | 2.480 | 2.840 | 190 | 185 | 4 | 3.170 | 4.150 | 2.300 | 195 | 168.800 |

| TAC 4.24/22 | 21,9 | 4 | 2.480 | 2.210 | 160 | 185 | 4 | 3.170 | 3.520 | 2.300 | 190 | 164.300 |

| TAC 4.24/24 | 24,0 | 4 | 2.480 | 2.420 | 160 | 185 | 4 | 3.170 | 3.730 | 2.300 | 208 | 180.000 |

| TAC 4.24/26 | 26,0 | 4 | 2.480 | 2.630 | 160 | 185 | 4 | 3.170 | 3.940 | 2.300 | 226 | 195.000 |

| TAC 4.24/28 | 28,1 | 4 | 2.480 | 2.840 | 160 | 185 | 4 | 3.170 | 4.150 | 2.300 | 244 | 210.700 |

| Scroll right |

Technical features

- Firebox and channels in refractory material with high content of aluminium oxide

- Mannesman pipes with no welding, independent for top and bottom of adjacent chambers, 27mm diameter and 4mm thickness, tested at 700 bar

- Independent steam generators for each chamber

- Baking surface in refractory concrete strengthened by steel jacket

- Doors made of steel and tempered glass, easy to disassemble

- Door opening upwards, with possibility to lock the door in open position, easily unlockable

- Electromechanic control panel

- Front in AISI 430 stainless steel

- Stainless steel AISI 430 baking chamber and side panels

- External hood made of AISI 430 stainless steel, equipped with fan for steam extraction

- Galvanized sheet covering

- Insulated stainless steel doors with or without glass window

- Exhauster fan in stainless steel

- Programmed oven power up with included automatic chimney valve opening

- Upper chamber with useful mouth passage of 22 cm (available only in 3 or 4 chambers models)

- Additional steam generator for proofer

- Hydraulic ramp for manual steam supplyin case of electrovalve failure

- Additional side firebox for solid fuels

- Motorized steam exhaust valve opening

- Double steamers (only for 248cm wide models)

- Burner

Try our ovens!

In our headquarter you can come and try your recipes working with a laboratory 4.0!

Fill out the form, you will be contacted in no time!